I already promised that there are going to be more detailed posts about the printing-techniques. (I mean...you waited long enough now.) So, here's the first of them:

Fdm

History

Who read my last blog post knows already that the fused deposit modeling is the oldest "printing" method. The technology was developed in the late eighties and commercialized in the early nineties by Stratasys, Inc. S. Scott Crump, the co-founder, and currently CEO, of Stratasys patented the FDM technology in 1989 with his wife and also co-founder, Lisa Crump. In 2003, the FDM-technology was the most used rapid prototyping technique.

Process

The model is - obviously - built layer for layer, either until the model is finished or there isn't any material available.

|

| The FDM-Process |

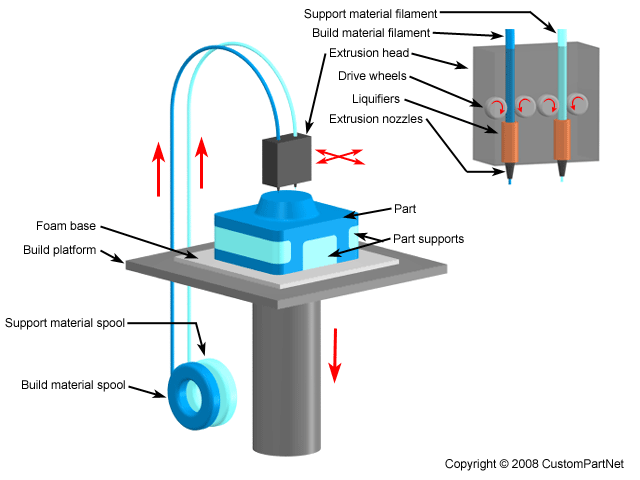

As you see on the graphic, the extruder/ the printing head or the platform where the model is built, is fixed. However, there are a few different ways of moving the extruder. The most common method to do this is the "cartesian"-system, but a different system - the so called "Delta-Printer" - is rising.

Material loading

The material used is stored on a spool respectively multiple different spools if there is more than one printhead. From the spool, the filament is led to the extruder. As you see, the material loading for the FDM process isn't too complicated. However this is very different for the other processes I am going to describe in here.

Extrusion

The extruder is the heart of any FDM-printer. It's the place where the stiff plastic filament gets molten and placed in the form of the model we want to achieve. The following graphic is pretty self-explaining, but I am going to say a few words along with it:

|

| Material-loading and extrusion |

Advantages

- It's cheap. As you may know, the cheapest 3d printer is the printrbot simple for only 300 Dollar. Compared to the much more expensive SLS/SLM/SLA-machines, even something like the makerbot is easily affordable.

- The filament is available in a great range of materials, and most of it is pretty cheap.

- Very compact build-style.

- Easy to operate and keep working.

Disadvantages

- Supports are required for complicated geometries. Although there are machines that use dissoluble materials for the support is this a limiting factor for this technology.

- If you want a clean surface, you have to go through post-processing. This is the effect of the layers.

- Lacking accuracy in comparison to the "bigger" printing-technologies like SLS.

I promise that there won't be such a big gap between this and my next post.

Cya

No comments:

Post a Comment